Sorry, we didn't get any result for

Frøslev Flamewood

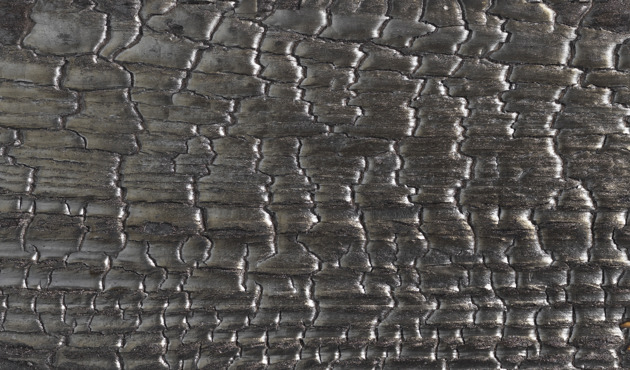

Frøslev Flamewood is wood with a surface that has been carbonised to a greater or lesser degree. It gives the wood a beautiful and unique surface – and at the same time protects the wood from the elements as well as attacks from dry-rot, insects and fungus. Inspired by the ancient Japanese burning technique Shou Sugi Ban, the treatment gives the wood a deep black to shiny silver colour that retains its beauty for many years.

Frøslev Flamewood is being produced in cooperation with Zwarthout|Shou Sugi Ban.

Why you should choose Frøslev Flamewood

- Beautiful and unique look

- Resistant to dry-rot, insects and fungus

- No chemical treatment

- Almost no maintenance

- Becomes more beautiful over time

- Various looks depending on the type of wood

- Can be used inside and outside depending on the carbonisation

Yoroi

Yoroi is made of heat-treated, FSC-certified bamboo from China. The boards are made by compressing the bamboo fibres after which the boards are individually and carefully burned in a special furnace. Yoroi gets a hard, carbonised surface with refined markings and a silver glow in the sun’s light.

Yoroi is specially designed to comply with fire class B. The bamboo has a good fire-retardant effect as a result of the heat treatment, and no further fire-proofing is necessary. There are many possible applications for Yoroi – inside as well as outside.

All wood is affected by the elements. But Yoroi generally weathers very slowly. However, small pieces of the carbonised surface may fall off after a few years. That has no impact on the coal layer or the underlying bamboo.

Naoshima

Naoshima is made with Douglas fir. After burning, it gets a deep, black colour that shines beautifully in the sunlight. Naoshima’s rustic look stems from the Japanese philosophy of wabi-sabi which is about seeing and embracing the beauty of the imperfect.

The structure is irregular with a sparkle that works well for vertical as well as horizontal installation. The outer millimetres of the surface of the wood are porous following carbonisation, and there are therefore certain construction requirements to reduce the impact of the elements. We therefore recommend to not use Naoshima for buildings higher than 6 m above ground level or in open areas with high wind exposure. The surface may rub off, especially at first, but is easily washed off with soap and water.

Douglas fir comes from sustainable and certified European forestry. Naoshima is a natural product, and no two boards are alike. There may also be knots that remain visible through the carbonised layer.

Patination and maintenance

Frøslev Flamewood becomes more beautiful over time

The fire-treated wood ages nicely as the carbonised surface develops a beautiful patina over time.

If the surface is only slightly burnt, it may fade over time if exposed to very direct sunlight. The deep, carbonised surfaces are less exposed.

Flamewood requires almost no maintenance

If Frøslev Flamewood is treated correctly, it will retain its beauty for years. Because of its carbonised surfaces, neither Naoshima nor Kazura requires any maintenance. The same applies to Yoroi. In very shady areas, however, green deposits may occur. Those can be removed with cleaning vinegar, lukewarm water, a soft brush and gentle treatment.

Over the years, the wood will begin to show small patches of peeling which may become greyish. This is normal and is part of the special characteristics of the product.

Be aware that the surface is vulnerable. Avoid physical and mechanical contact. If necessary, algae growth can be cleaned with water or a mild wood cleaner. Use a spray bottle or a clean garden sprayer if the surfaces are large. If the surfaces become dusty, dust gently with a feather duster or a slightly dampened, lint-free cloth.

Do not use a high-pressure cleaner as it will ruin the carbonised surface. Avoid using abrasive scouring agents and do not scrub the surface as that will also damage the treatment.

In case of extensive damage, we recommend replacing the entire board.

How Frøslev Flamewood is being produced

The production of Frøslev Flamewood is quite simple. The surface of the wood is burned under controlled conditions until the desired look is achieved. It is then cooled with water and cleaned. The process makes it unnecessary to impregnate the wood using any other methods.

The process of burning the wood surface causes the sugary substances to break down which prevents attacks by dry-rot, insects and fungus.