Sorry, we didn't get any result for

Sature

Sature® is silicate-impregnated quality pine from certified Nordic forests and is a new, ground-breaking material for the construction industry. The silicate impregnation consists of sand (silicate) and water and is an impregnation that protects the wood from dry-rot and fungus so it can last year after year. Sature® is strong, durable and especially suitable for terraces and cladding and is a good alternative to pressure-impregnated wood.

Why you should choose Sature

- Strong and durable for outdoor use

- Impregnated with sand (silicate) and water

- Free from biocides and heavy metals

- Patinates in a short time and becomes all light

- Central Swedish/Finnish fifth quality

- Certified, Nordic quality pine

- Durability class 2

Certifications

Sature is PEFC certified and declared by EPD Denmark. Read more about all the certifications here.

Perfect for façades and terraces

Sature® is made for cladding of façades and terraces in the Danish climate. The silicate modification increases the durability, strength and hardness of the wood, and the wood is therefore very suitable for outdoor cladding. Sature is for anyone who wants light and Nordic wood that is strong, durable and impregnated with nature’s own forces and with respect for the environment. The product does not tolerate permanent soil or water contact.

Terraces

A wooden terrace furnished with beautiful lounge furniture, flower pots and perhaps even terrace heaters gives the house a cozy extra room and extends the summer in the garden. And with wood from Frøslev, you can be sure to get a high-quality terrace that can be the gathering point for friends and family for many years.

Facades

Sature is perfect for facades. Mounted on facades, it can stand without further finishing. Over time, the facade will patinate to a light, grey colour.

Patination and maintenance

Sature patinates into very light wood

Sature, mounted on the facade, can be left without any further surface treatment. Sature decking must be maintained once a year with Sature care products. The wood patinates over time into all light wood. The patination depends on the elements, structural protection (e.g. eaves) and the location of the façade or the terrace in relation to the sun. Despite the patination, Sature retains its protective properties.

A white layer from the treatment of the wood may appear on the surface. It can be brushed off but will disappear in the rain.

Use Sature care products

Sature cannot be painted or oiled. For installation and care, Sature care products must be used instead. All Sature care products are water-based and are sold together with the wood. Detailed instructions for use are provided on the packaging.

How we produce Sature

Sature® is impregnated under pressure at our own plants with Sature impregnation which consists of sand (silicate) and water.

The wood is impregnated with silicate.

The process involves a physical blockage of the cells in the wood. Therefore, modification of wood using silicate is a form of petrification. Once the fluid has been put into the wood, the water will evaporate, and all that is left are silicate molecules in cavities and in the pore structure.

Impregnation increases density, strength and hardness of the wood by 20-25 %. Wood-decay fungi use a lot of water to make wood decay, and Sature is therefore extremely resistant to fungal attacks.

Tested and validated

It took Preservation Technologies 10 years to develop Sature. Several universities and independent testing institutes participated with advice and testing in the development phase during which the hardness, strength and durability of the wood were tested in the harshest climate conditions in the world, among other places in Austria, France and Borneo.

This is how Sature is made

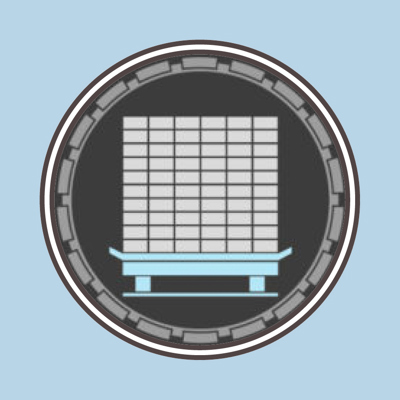

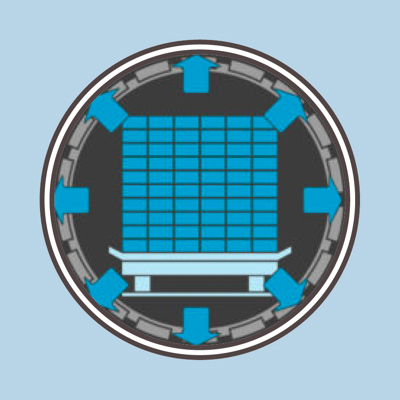

Step 1

The wood is placed in specially developed steel tanks

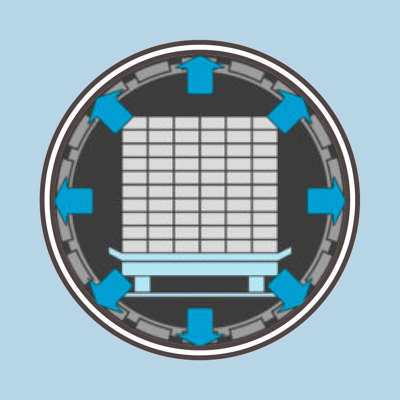

Step 2

All air is sucked out of the tank

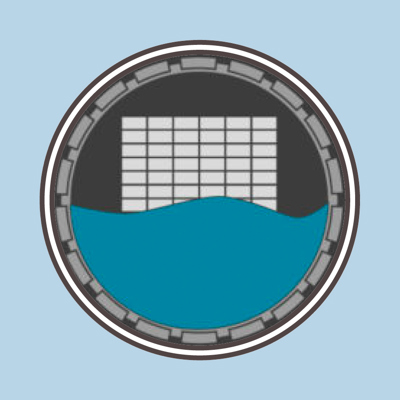

Step 3

The tank is filled with the modified silicate liquid

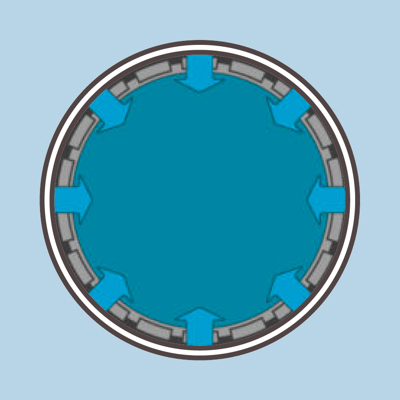

Step 4

Under high pressure, the silicate is pressed into the wood

Step 5

Excess liquid is pumped out and stored for later use

Step 6

After drying, Sature is ready for use

The technology behind Sature was developed in collaboration between Bollerup Jensen and Frøslev.

Read more about the technology on Sature.dk

Documentation and downloads

Strengthened EU regulations

Have you heard about the new, stricter EU requirements for fire testing of wood cladding, such as pressure-treated wood or ThermoWood? All our products are fire-tested and already comply with the new requirements. Read more